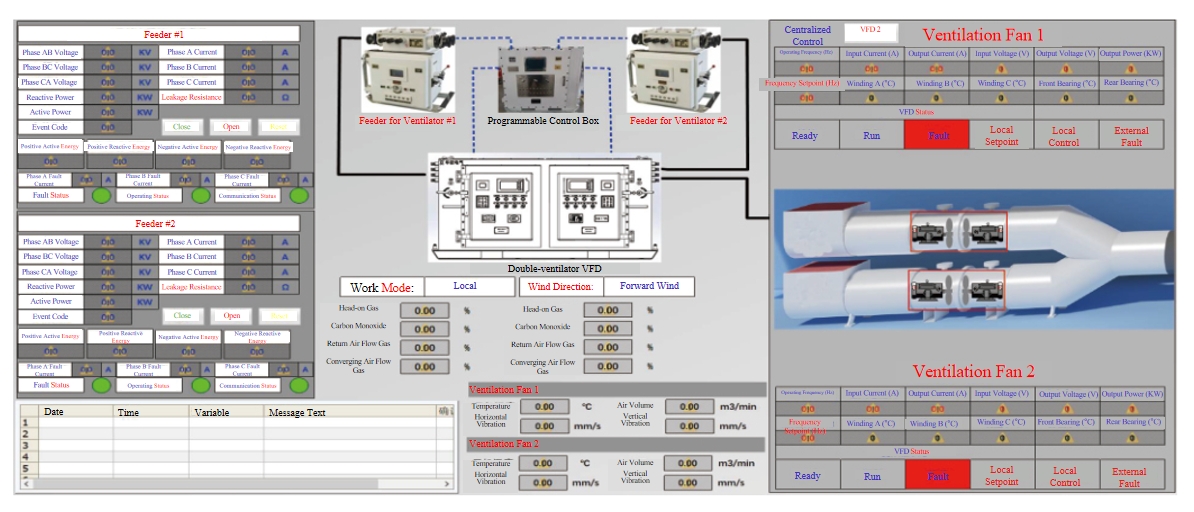

1. The Local Booster Ventilation Monitoring System is composed of a ground monitoring station, programmable control box, ventilation fans dual power supply redundant VFD, electric feeder, and various environmental parameter sensors. The control box collects feeder contact status and VFD data through RS485, and transmits the data to the ground monitoring center through the Ethernet ring network.

2. The local booster ventilation fan is an essential piece of equipment for underground gas discharge in coal mines during the drilling and excavation processes. It provides fresh air flow for the drilling face, discharging hazardous gases and dust, improving environmental conditions at the workface, and diluting and discharging accumulated underground gas. Proper use and control of the local ventilation fan is an important guarantee for coal mine safety. 3. The ventilation monitoring system of can realize maximum automated management and control of underground local ventilation fan under the requirements of Coal Mine Safety Regulations, thus achieving the following goals:

4. Fast and complete restoration of ventilation for non-fault stoppage to ensure the safety of the excavation route;

5. Automated hierarchical air supply based on the production environment requirements for gas and air volume to achieve noise reduction and energy conservation;

6. Remotely or locally start, stop, and test the switching equipment, and upload crucial operation statistics for easy control and management, staff reduction and efficiency improvement;

7. Carry out automatic gas discharge;

8. By analyzing statistic data, classified data can be easily obtained, and the operating status of all associated devices can be easily accessed, allowing potential faults to be predicted in advance.

|

S/N |

Name | Model Description | Quantity |

|

1 |

Programmable Control Box |

KXJ127 |

1 set |

|

2 |

Operating Console |

TH1-24 |

1 set |

|

3 |

Industrial Computer |

IPC- 610L, Win10 Pro |

1 set |

|

4 |

Computer Monitor |

27-inch Display |

1 set |

|

5 |

Host Computer Software |

Customized according to site requirements |

1 set |

|

6 |

Ethernet Switch |

1000M/100M Managed Switch |

1 unit |

|

7 |

Mining Gas Sensor |

Measuring Range: 0.00~4.00% CH4; Response Time: Less than 20s; Output Signal: 200~1000 Hz |

Several |

|

8 |

Carbon Monoxide Sensor for Mining Applications |

Measuring Range:0~1000*10-6CO; Operating Voltage:9-24V; Output Signal:200~1000 Hz |

Several |

|

9 |

Intrinsically-safe Vibration & Temperature Sensor for Mining Applications |

Speed Range: 0-20mm/s; Temperature Range: -20-100℃; Signal Output: 4-20Ma dual output |

Several |

|

10 |

Mining Airflow Pressure Sensor |

(0.00 to 5.00)KPa, Frequency Output |

Several |

|

11 |

Bilateral Air Velocity Sensor for Mining Applications |

(0.4~15)m/s, Frequency Output |

Several |