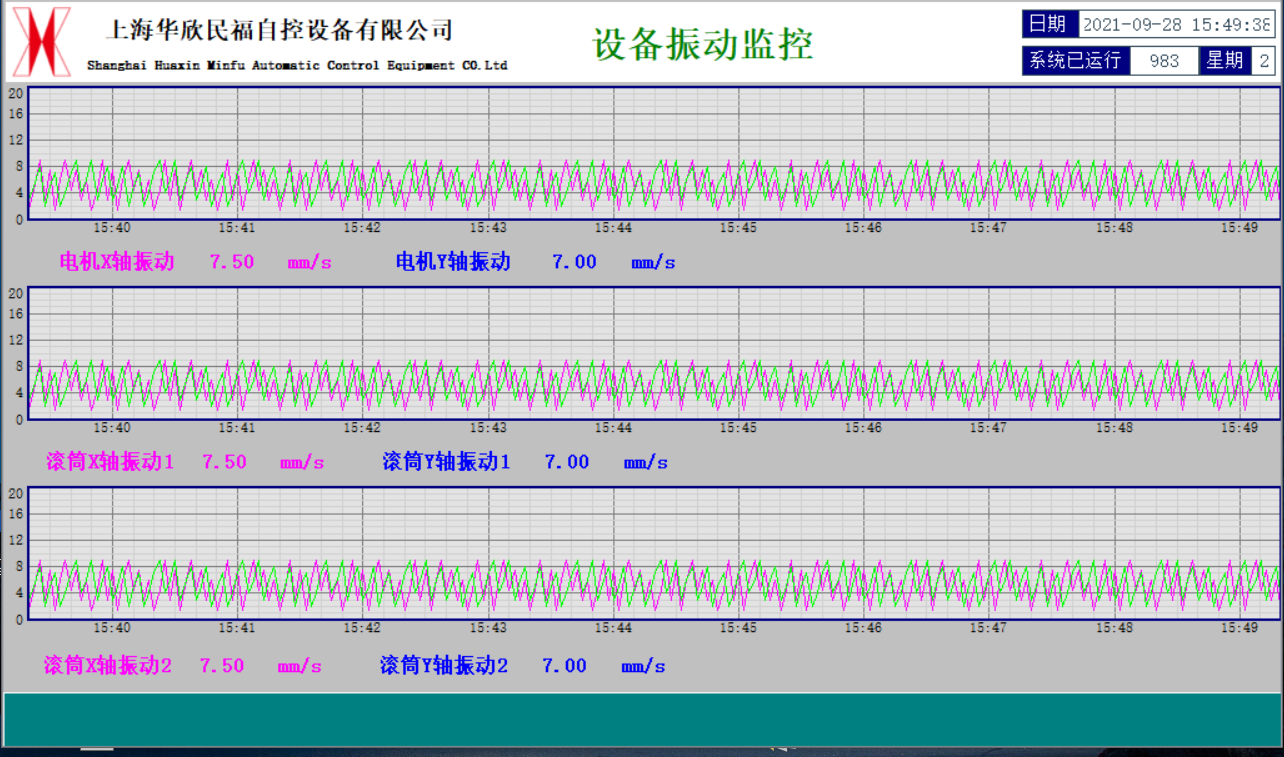

ZJZW 127 Vibration and Temperature Monitoring Device for Coal Mining Electromechanical Equipment

According to the relevant requirements of the National Coal Mine Safety Administration, the motors and the main bearings of all key equipment used in mines need to be subject to real-time temperature and vibration monitoring. In response to national construction and safety requirements, we have developed a vibration and temperature monitoring device composed of intrinsically-safe vibration & temperature sensors, the flame-proof and intrinsically-safe control box, an industrial computer and data analytics software. The supporting data analytics software offers data recording, data access, trend analysis, alarm records, querying and other functions. Through the online waveform chart, the current temperature, vibration data, historical data and waveforms can be viewed in real time. The device is a continuous monitoring system, able to collect the relevant temperature and vibration data of the equipment and keep the operator informed of the real-time status of the equipment, so as to find any potential faults in time and identify operating status and equipment faults in a timely manner.

Explore More

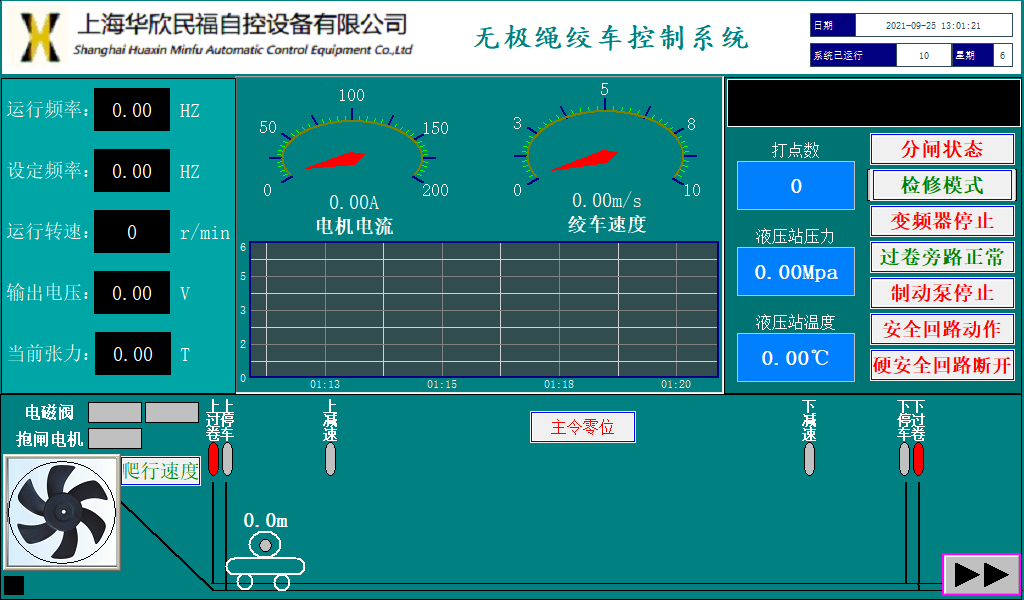

Electric Control Device for Rail Endless Rope Driven Transport System

The digital control system of the endless rope winch features a set of PLC, and handles the control, safety interlocking and fault protection of the endless rope winch according to the feedback from position and speed sensors, as well as operation signals from the leaky feeder communication system. It boasts an advanced, reliable performance, and is easy to operate and maintain.

Explore More

KHP357- K Belt Conveyor Protection and Control System

The integrated coal mine belt conveyor protection and control device is suitable for scenarios where gas (methane) and coal dust is present, including mining faces, transportation roadways, shaft stations, belt conveyors, coal storage yards, and other working environments with risks of explosion. The programmable controller is used to realize the total monitoring and protection of the underground belt conveyor, which features strong applicability, scalability, high reliability and powerful communication ability.

Explore More

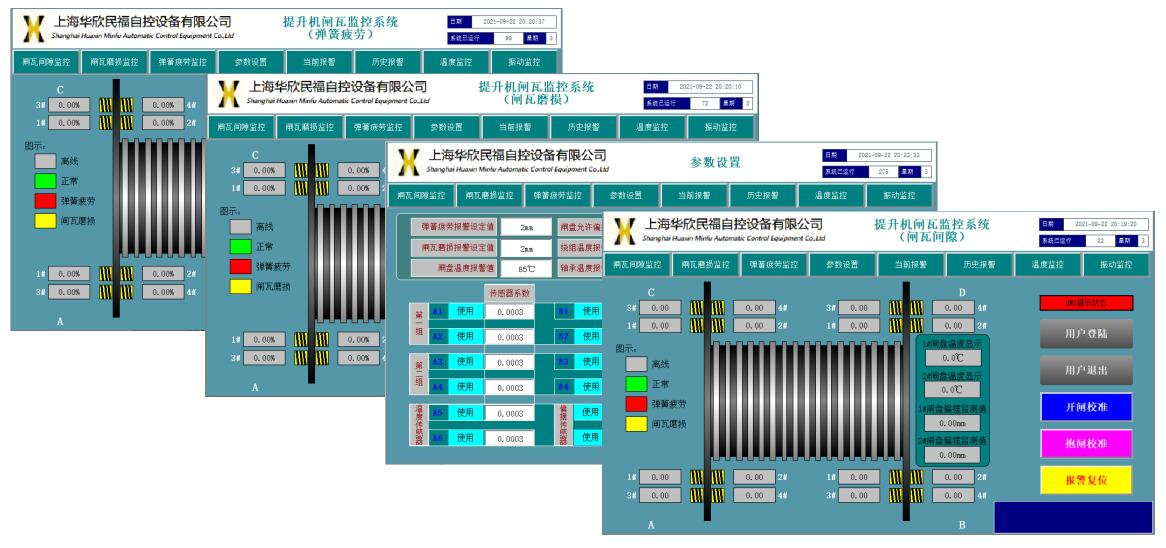

ZZJT127 Hoist Brake Gap Monitoring Device for Mining Applications

The device consists of KXJ127 Flame-proof and Intrinsically-safe Programmable Control Box for Mining Applications, GUD10 Intrinsically-safe Position Sensor for Mining Applications, BYD4 Intrinsically-safe Pressure Transmitter for Mining Applications, GWK42 Intrinsically-safe Temperature Sensor for Mining Applications, and PVC insulated copper wire shielded soft control cable for coal mines. The device supports up to 24 channels of analog data acquisition, which is used to detect the brake pads wear and spring fatigue of coal mine hoist. The device is controlled by a PLC, ensuring good anti-interference performance, high reliability and programmability. It is equipped with a 10-inch color display to dynamically show the gap between brake disc and pads, and simulate the disc brake movement through animation. Good HMI interaction, easy to use and operate.

Explore More

ZPS1140(660) Automatic Mine Drainage Device

The automated drainage system is composed of a ground monitoring station, programmable control box, operating console, jet pump assembly, electric brake valve and various sensors. The industrial Ethernet ring network is used as the backbone of the underground pump station monitoring system to ensure real-time data transmission for related equipment in the pump station. All of the pump station data is fully integrated into the mine monitoring system.

Explore More

Signaling System for Mining Hoist Applications

The system is controlled by a PLC. The network uses fieldbus communication; the communication network runs through shielded multi-pair cables or armored fiber optics, while fail-safe control signals are connected with hard-wired cables;

The system has a number of external interfaces, and can be seamlessly connected with other related devices such as the mine cart operating system;

The system has a power supply voltage of 127V AC, and is equipped with special isolation transformers, offering strong anti-interference capabilities. The primary and control current circuits are wired separately. The entire control system features a compact structure, a variety of functions, stable operation, reliable performance, good adaptability, and good anti-static measures.

Explore More

ZTK (A) Electric Flame-proof Hoist Control Device for Mining Applications

The device is combined with various VFDs for mining applications to form a mine hoist frequency conversion control system, which is suitable for underground coal mines and other locations containing coal dust, gas or other flammable and explosive gases. This includes inclined underground shafts, single level, multi-level, single-drum, and double-drum mine hoists.

Explore More

ZR(A) Electric Control System for Coal Mine Cable Car

The system is equipped with a ground monitoring system which can monitor the operating status of the cable car in real time, as well as record and save related data. The system can also control start/stop, reset faults, and configure parameters. The SCADA (supervisory control and data acquisition)

computer and the underground control system are connected via fiber optic cables, with data transmitted using the TCP/IP protocol.

Explore More