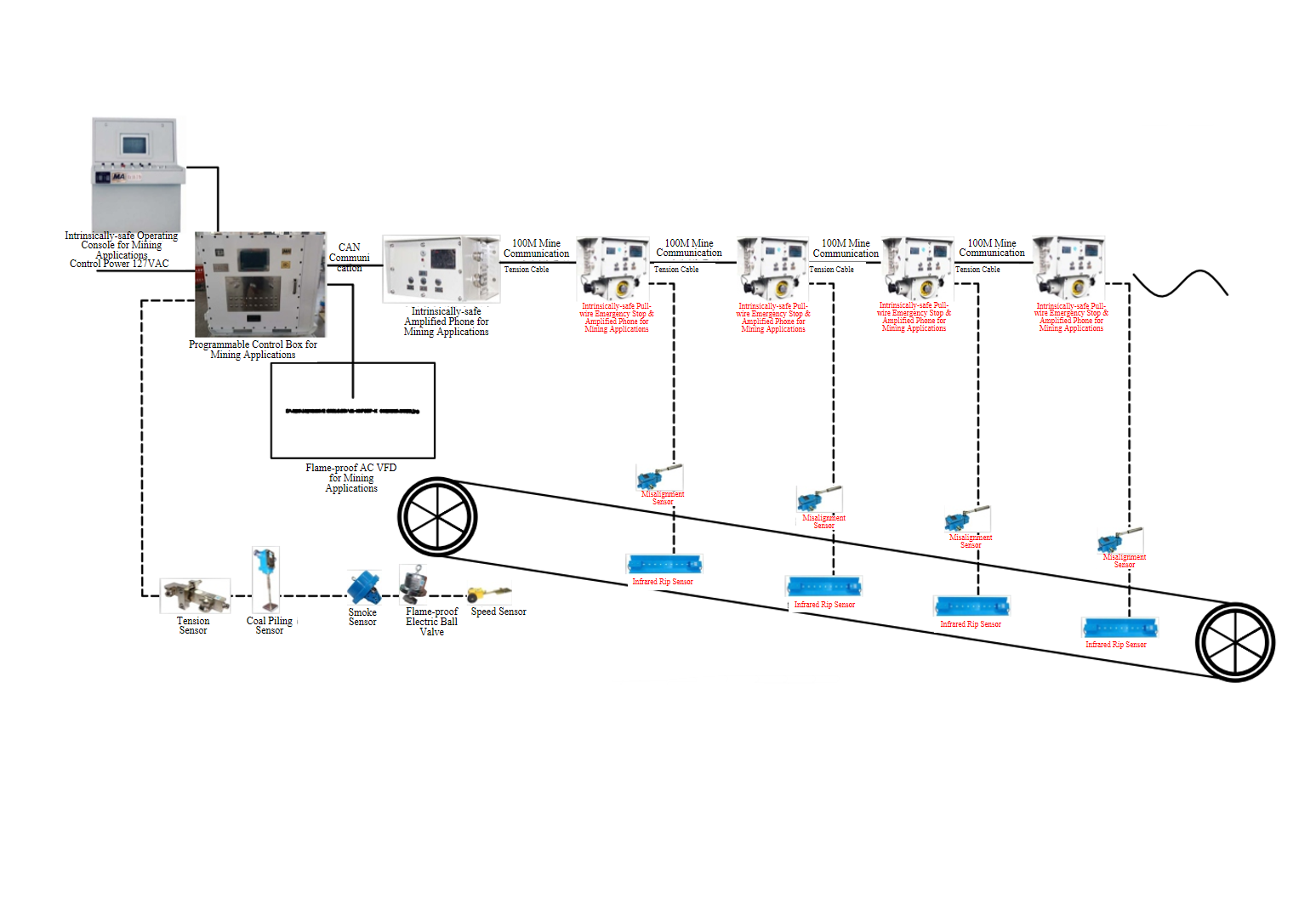

The integrated coal mine belt conveyor protection and control device is suitable for scenarios where gas (methane) and coal dust is present, including mining faces, transportation roadways, shaft stations, belt conveyors, coal storage yards, and other working environments with risks of explosion. The programmable controller is used to realize the total monitoring and protection of the underground belt conveyor, which features strong applicability, scalability, high reliability and powerful communication ability.

The system can collect real-time data related to speed, tension, voltage, current, oil pressure, oil level, brake status, coal level, temperature and vibration during belt operation.

The system offers eight protections for the conveyor belt system: temperature protection, speed protection, smoke protection, coal piling protection, misalignment protection, tension protection, tear protection, slip detection, emergency stop protection, and over-temperature fire sprinkler system.

Intelligent integration: The steel reinforced cable provides path for the power supply, the audio signal, inter-locking signal, and the emergency stop signal. Terminals along the cable adopt a quick-connect design. The intelligent protection system is formed by multiple Intrinsically-safe Pull-wire Emergency Stop with Amplified Phones via CAN fieldbus communication. Through an armored cable that runs along the belt, the device audio, interlock, pull-wire emergency stop, digital communication, and device power supply are integrated, while the armored cable can also be used as a pull rope for the emergency stop lockout switch. The cable features stainless steel and U-pin quick connectors;

Connects the interlocking input from the upstream belt and the interlocking output to the downstream belt, provides belt interlocking, belt and coal feeder interlocking functions. The interlocking output is delivered by the phone relay switches along the line;

The programmable controller can automatically identify and display the type of equipment along the line (lockout, amplified phone, sub-station or other equipment), the address sequence is automatically assigned by the master controller, with no manual configuration or address setting required; the control length of a single line can reach up to 4 kilometers without amplifier;

Voice alarm: The belt protection device features a start and stop warning system; the amplified phone has batteries and can operate normally even in the event of power outage.

Through the sound voice alarm function, voice alarms and reminders can be given for the starting and stopping of a single device, as well as for the operation and fault status of the equipment along the belt line, fault name and fault location, and various sensor access problems.

Through the optical fiber ring network, the industrial standard communication protocol is used for remote server configuration, centralized data processing, storage and access, thus achieving centralized control;

|

S/N |

Name |

Model Description |

Quantity |

|

1 |

Programmable Control Box |

KXJ1-127 |

1 set |

|

2 |

Operating Console |

TH1-24 |

1 set |

|

3 |

Intrinsically-safe Pull-wire Emergency Stop with Amplified Phone for Mining Applications |

Calling, dotting, voice alarm, press the lock button or pull the cable for emergency stop lockout along the line |

Several |

|

4 |

100M Mine Communication Pull Wire Cable |

MHYPBV-100M |

Several |

|

5 |

Tension Sensor |

Operating Voltage: DC12~24V; 5T~20T Optional; DC4~20mA Output |

Several |

|

6 |

Intrinsically-safe Mining Coal Level Sensor |

Operating Voltage: DC12~24V; Angle of Movement: 15⁰ ±3°. Signal Output: Passive Switch; Contact Capacity: 24.5V/ 1A; |

Several |

|

7 |

Intrinsically-safe Smoke Detector for Mining Applications |

Operating Voltage: DC12~24V; Operating Current: less than 120mA; Sensitivity: Level II; Output Signal: contact is open when no smoke; Contact closes when smoke is detected. |

Several |

|

8 |

Flame-proof Electric Ball Valve for Mining Applications |

Operating Voltage: AC127V; Operating Current: ≤0.3A; Open/close Time: ≤15S; Water Supply Pressure Range: 0.2~ 7MPa; |

Several |

|

9 |

Intrinsically-safe Speed Sensor for Mining Applications |

Operating Voltage: DC12~24V; Range: 0~10m/s; with rollers; contact type |

Several |

|

10 |

Intrinsically-safe Misalignment Sensor for Mining Applications |

Angle of Set: 30⁰ ±3°; Angle of Reset: 15⁰ ±3°. Contact Capacity: 24.5V/1A; |

Several |

|

11 |

Intrinsically-safe Tear Sensor for Mining Applications |

Infared, Contact Output; Contact Capacity: 24.5V/ 1A; |

Several |

|

12 |

Intrinsically-safe Infrared Temperature Sensor for Mining Applications |

Operating Voltage: DC12~24V; Output: 4mA ~ 20mA; Corresponding Temperature Range: 0 ~ 100 degrees Celsius; |

Several |