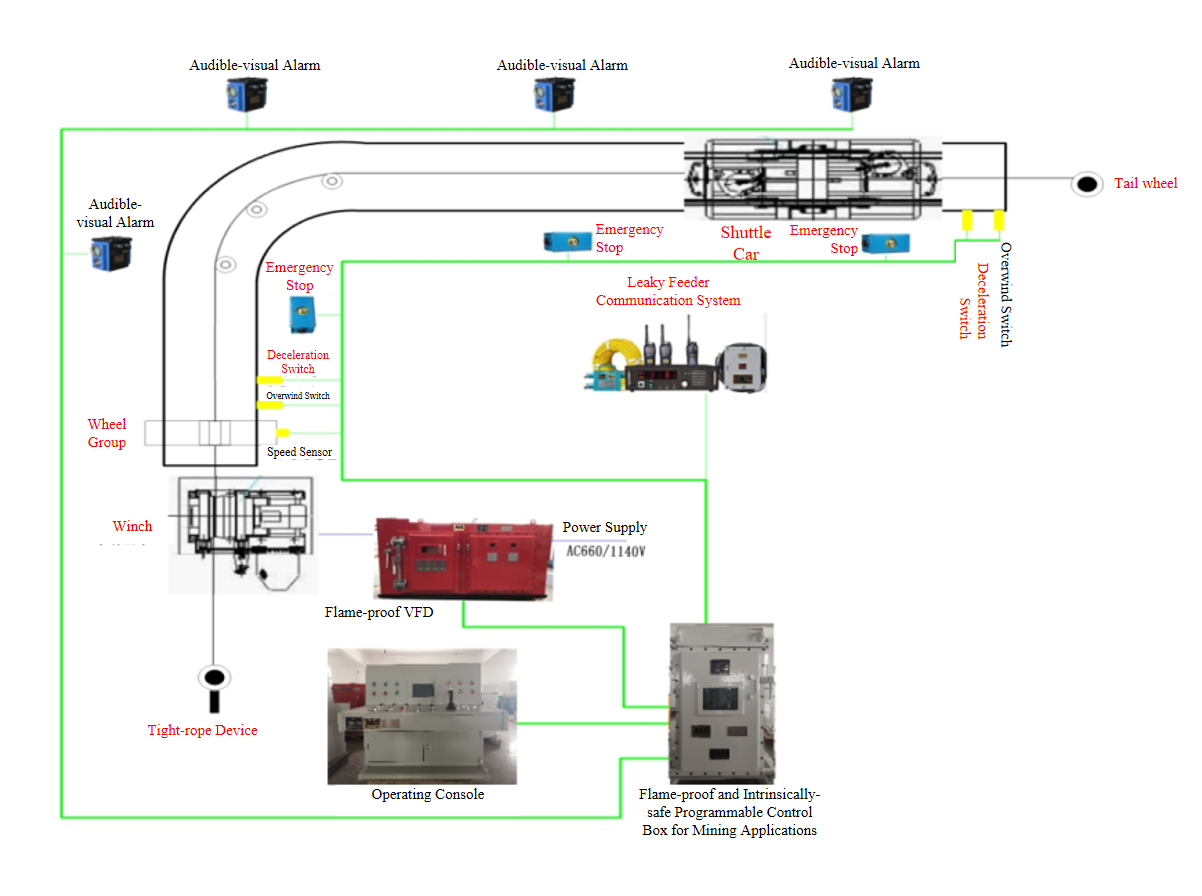

The digital control system of the endless rope winch features a set of PLC, and handles the control, safety interlocking and fault protection of the endless rope winch according to the feedback from position and speed sensors, as well as operation signals from the leaky feeder communication system. It boasts an advanced, reliable performance, and is easy to operate and maintain.

Provide forward and reverse start/stop control and protection for rail endless rope driven transport system ;

Position based protections: over-winding, deceleration; speed protections: overspeed, skid, and off track; other protections: emergency stop along the line, auxiliary equipment protection, oil pressure protection, motor temperature protection, etc.

Controls the brake discs and the main motor fan;

Allows interlocking of the leaky feeder system start/stop signal and the endless rope electric control circuit. The control system provides lockout of overwinding direction and driving direction, lockout of safety circuit and brake device, the interlocking of the external protection system and safety circuit, and mutual lockout with the leaky feeder system , as well as lockout of hardware and software safety circuits.

Carries out mobile handset emergency stop, dotting, calling and other functions together with the coal mine leaky feeder communication system; features high-performance PLC, optoelectronic isolation of Intrinsically-safe and non-Intrinsically-safe circuits;

The 10.4-inch color LCD can display, access and store more content, including current, running speed, shuttle car location, motor temperature, motor current and real-time curve of running speed, as well as a list of current faults and fault history.

1. KXJ-158-25/660(A) Flame-proof and Intrinsically-safe Programmable Control Box for Mining Applications

2. TH1-24 Intrinsically-safe Operating Console for Mining Applications

3. PB2-24 Flame-proof Display Box for Mining Applications

4. BQH24 Intrinsically-safe Encoder for Mining Applications

5. Leaky Feeder Communication System

6. Wireless Video Surveillance System