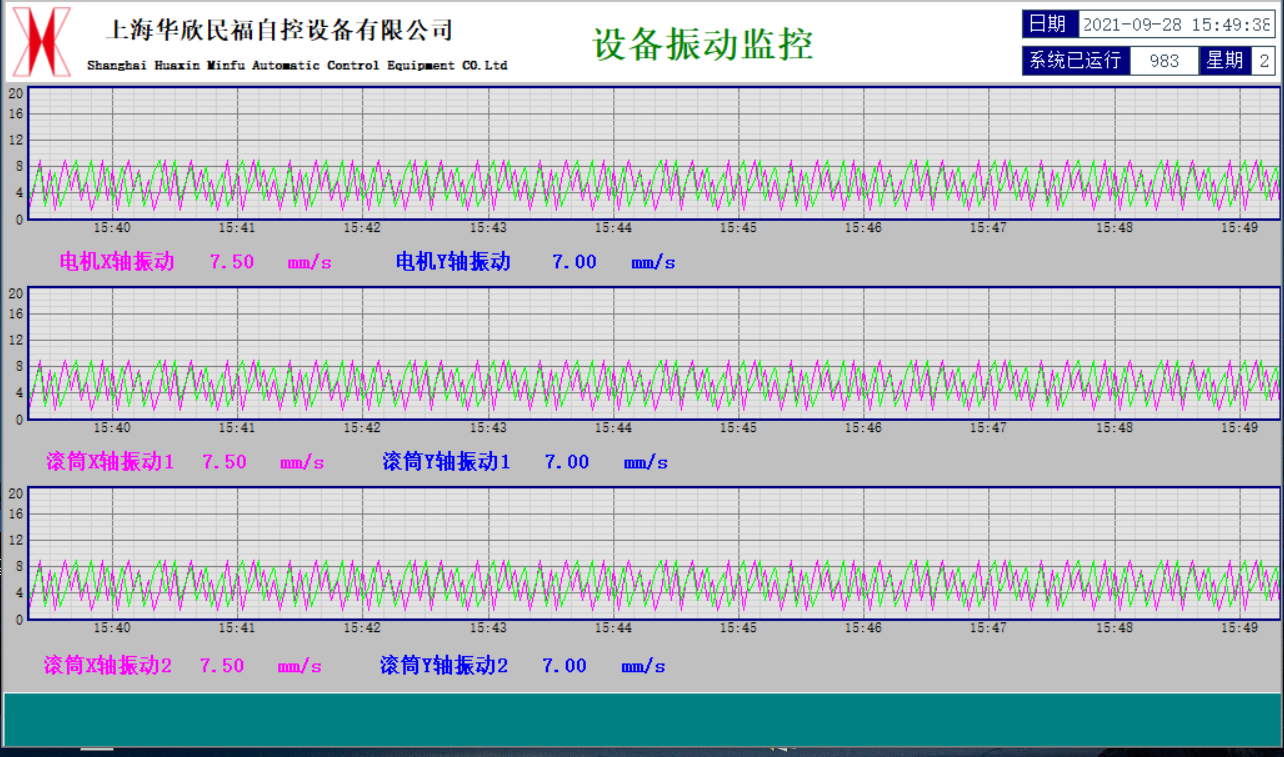

According to the relevant requirements of the National Coal Mine Safety Administration, the motors and the main bearings of all key equipment used in mines need to be subject to real-time temperature and vibration monitoring. In response to national construction and safety requirements, we have developed a vibration and temperature monitoring device composed of intrinsically-safe vibration & temperature sensors, the flame-proof and intrinsically-safe control box, an industrial computer and data analytics software. The supporting data analytics software offers data recording, data access, trend analysis, alarm records, querying and other functions. Through the online waveform chart, the current temperature, vibration data, historical data and waveforms can be viewed in real time. The device is a continuous monitoring system, able to collect the relevant temperature and vibration data of the equipment and keep the operator informed of the real-time status of the equipment, so as to find any potential faults in time and identify operating status and equipment faults in a timely manner.

The control center computer reads the data from all monitoring remote stations through standard communication protocol, and analyzes, displays and saves the data for easy access.

The flame-proof and intrinsically-safe programmable control box for mining applications is used to collect field data; the built-in PLC and Ethernet switch support Profibus, Modbus RTU, MODBUS-TCP and other communication protocols for easy integration with the monitoring system.

Sensor Parameters:Power Supply: Ui:24.5V, Ii:0.5 A, Ci:0.1μF, Li:0.1mH Vibration Signal Output: 4~20 mA/0-200mm/s Temperature Signal Output: 4~20 mA/0-110°C Overall Dimensions: H63mmX D25.4mm; Weight: 130g. The housing material is stainless steel.

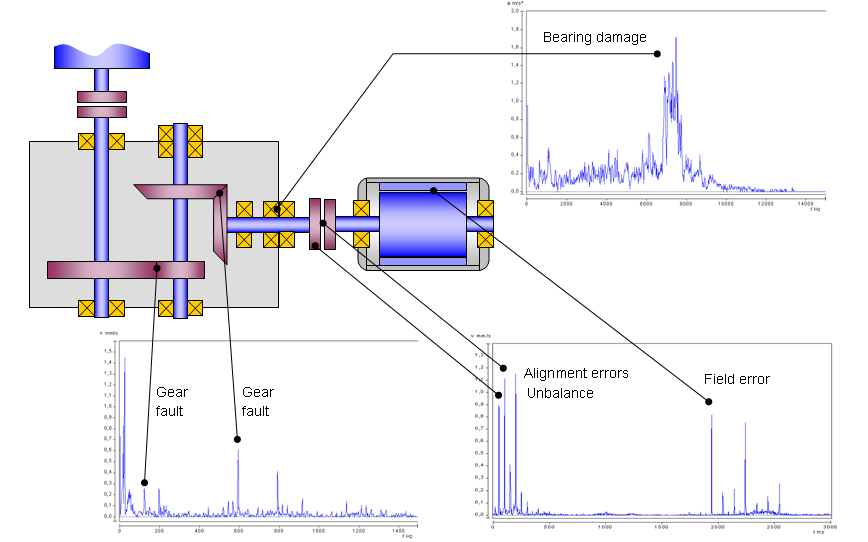

Uses the positive piezoelectric effect of piezoelectric materials.

Built-in precision integration circuit.

Used to measure the absolute vibration velocity of mechanical devices.

Can be installed vertically, horizontally or at any angle.