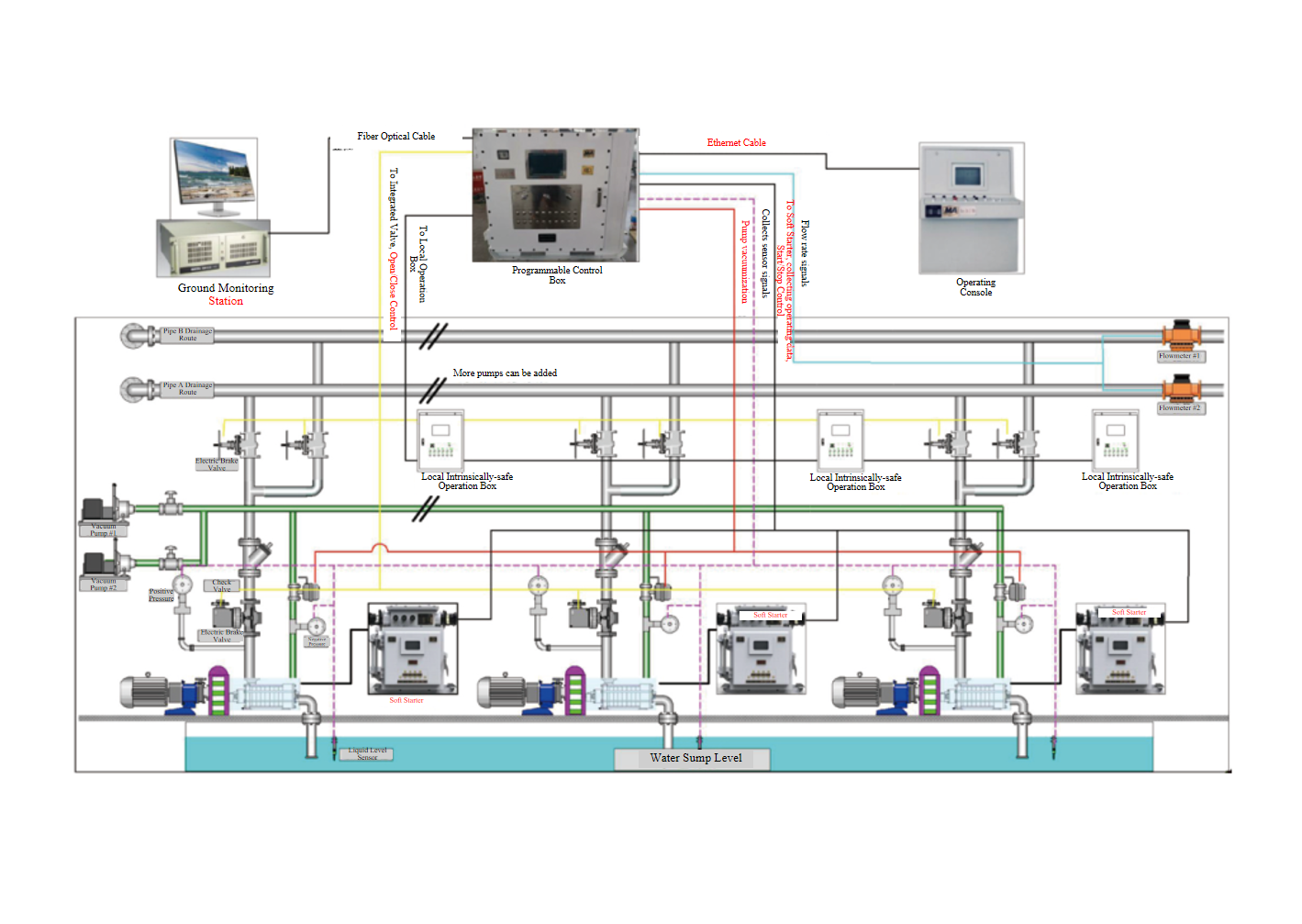

The automated drainage system is composed of a ground monitoring station, programmable control box, operating console, jet pump assembly, electric brake valve and various sensors. The industrial Ethernet ring network is used as the backbone of the underground pump station monitoring system to ensure real-time data transmission for related equipment in the pump station. All of the pump station data is fully integrated into the mine monitoring system.

The control system is designed with centralized/local, semi-automatic and fully automatic control modes;

In the fully automatic mode, there is no need of human intervention, with automatic control carried out by computer; the pump is automatically started and stopped according to the water level, while pump rotation is automatically achieved depending on the length of operation; suitable scheduling is made for peak filling;

Centralized control mode by ground computer and local control mode by underground operating console are both available;

The system has good real-time performance, with operating and protection parameters of the motor and water pump monitored and collected in real time, including axle temperature, real-time flow rate, water level, vacuum degree, voltage, current, pressure at water pump outlet, and position signals of various brake valves and solenoid valves.

Real-time data, event records and alarm records are stored in the database; curves and reports are generated according to the selected time period, and can be accessed and printed at any time;

The detailed, visual and intuitive content displayed on the HMI is easy to operate and understand;

A large number of control strategies are embedded in the software, enabling different decisions to be made depending on the actual situation, greatly improving the degree of automation and intelligence of the system;

Depending on the specific situation of different time periods, the operating parameters of the software can be adjusted to adapt to complex situations and improve the flexibility of the system;

| Name | Model Description | Quantity |

| Flame-proof and Intrinsically-safe Display Box for Mining Applications (Central Control Box) | KXJ-127 | Several |

| Flame-proof and Intrinsically-safe Programmable Control Box for Mining Applications (Local Control Box) | KXJ2-14/1140(660) | Several |

| Operating Console | TH3-24 | 1 set |

| Operation Box | CXJ1-24 | Several |

| Industrial Computer | IPC610L, Win10 Pro | 1 set |

| Computer Monitor | 27-inch Display | 1 set |

| Computer Software | Customized according to site requirements | 1 set |

| Ethernet Switch | 1000M/100M Managed Switch | 1 unit |

| Air-water jet assembly | DN25, air-water jet pump,vacuum gauge and pressure gauge | Several |

| Mine Pressure Sensor (Positive Sensor) | 0-10MPa,4-20mA | Several |

| Differential Pressure Sensor (Negative Pressure) | -0.1~1MPa,4-20mA | Several |

| Intrinsically-safe Submersible Level Sensor for Mining Applications | Range 0-10m.4~20mA, with display | Several |

| Intrinsically-safe Vibration & Temperature Sensor for Mining Applications | Speed Range: 0-20mm/s; Working Power: 24VDC; Signal Output: 4-20Ma | Several |

| Flame-proof and Intrinsically-safe Ultrasonic Flowmeter for Mining Applications | Power Supply: AC85~264V; Output: 4-20mA | 2 sets |

| Intrinsically-safe Infrared Temperature Sensor for Mining Applications | Range 0-100℃, 4mA~20mA | Several |

| Electric Brake Valve for Mining Applications | Configured according to site requirements | Several |

| Check Valve | Configured according to site requirements | Several |