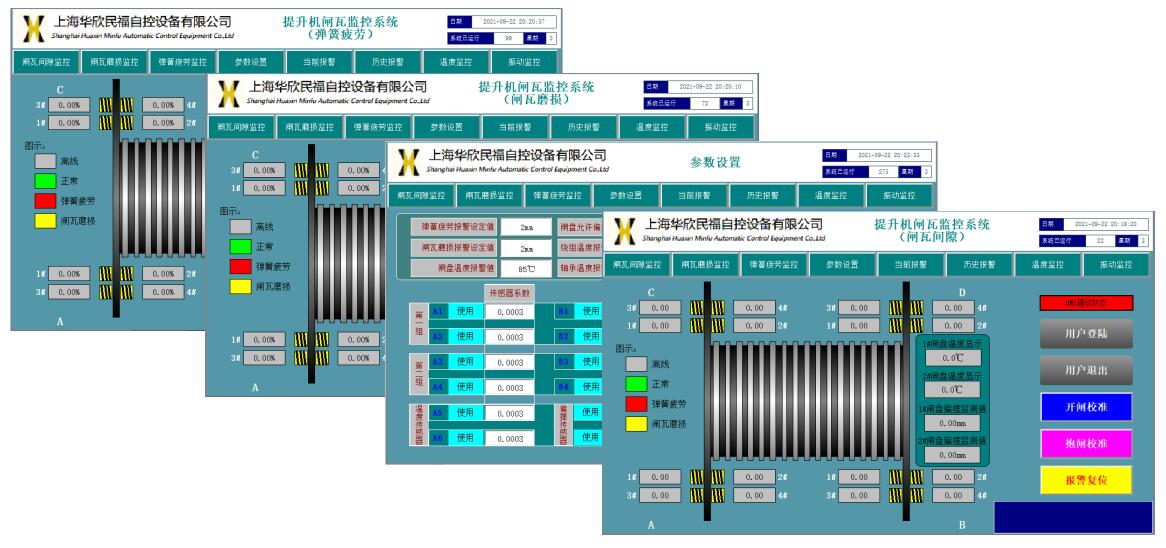

The device consists of KXJ127 Flame-proof and Intrinsically-safe Programmable Control Box for Mining Applications, GUD10 Intrinsically-safe Position Sensor for Mining Applications, BYD4 Intrinsically-safe Pressure Transmitter for Mining Applications, GWK42 Intrinsically-safe Temperature Sensor for Mining Applications, and PVC insulated copper wire shielded soft control cable for coal mines. The device supports up to 24 channels of analog data acquisition, which is used to detect the brake pads wear and spring fatigue of coal mine hoist. The device is controlled by a PLC, ensuring good anti-interference performance, high reliability and programmability. It is equipped with a 10-inch color display to dynamically show the gap between brake disc and pads, and simulate the disc brake movement through animation. Good HMI interaction, easy to use and operate.

1. Real-time online measurement and display of brake gap value (between pads and disc) with an accuracy within ±0.1mm;

2. Real-time on-line measurement and display of brake oil pressure with an accuracy within ±0.1MPa;

3. Brake gap value parameter self-calibration and over-limit alarm.

4. Brake oil pressure parameter self-calibration and over-limit alarm; brake pads failure protection;

5. Auto-correction of brake gap calculation error;

6. Self-diagnosis of system faults;

7. History alarm record and query: history fault records can be accessed to facilitate understanding of disc brake pads wear;

8. Online or offline modes available, for convenient inspection and maintenance;

9. The alarm output contact provided by the brake gap over-limit ensures the interlock function with the hoist master control system;

10. Disc spring fatigue overlimit warning, providing an alarm output contact;

11. Brake pressure monitoring reminder;

12. Brake disc runout detection;

13. Real-time monitoring of brake disc temperature and alarm reminder in case of over-temperature;

14. Dynamic display of brake gap (between disc and pads) and animated simulation of disc brake movement;

15. Conforms to the networking requirements of intelligent mines: features Modbus RTU; TCP/IP and other standard communication interfaces.

1. KXJ-127 Flame-proof and Intrinsically-safe Programmable Control Box for Mining Applications;

2. GUD10 Intrinsically-safe Position Sensor for;

3. Mining Applications MKVVRP Shielded Soft Control Cable for Mining Applications;